The motors were in, the battery boxes screwed on and makeshift ankle wedges in place for R2 to start rolling using a RC transmitter and receiver from the very first thing I bought with my very first credit card - a Tamaya Ford Escort Cosworth. R2 gently made his way through all the cars and positioned outside the window for all the guests to see. And to be honest I was pretty chuffed with how he was going, turning on the spot, forwards, backwards - absolutely fantastic. The best bit was how surprised the wife was - helps negotiate for more funds.

This is a website showing mainly the build and progress of our R2D2 unit. I am also going to show some photos etc of a Toy Land Rover I built for my 8yr daughter.

Sunday 30 December 2012

YEE!! HAAA! Movement

As expected, after a frantic Xmas eve troubleshooting, R2-ST was ready for movement on Boxing Day.

The motors were in, the battery boxes screwed on and makeshift ankle wedges in place for R2 to start rolling using a RC transmitter and receiver from the very first thing I bought with my very first credit card - a Tamaya Ford Escort Cosworth. R2 gently made his way through all the cars and positioned outside the window for all the guests to see. And to be honest I was pretty chuffed with how he was going, turning on the spot, forwards, backwards - absolutely fantastic. The best bit was how surprised the wife was - helps negotiate for more funds.

Inspired by the above success, a thorough clean of the workbench and floor in the DMW was followed by some gentle soldering on the rear PSI board. This was hooked up to the rear logic and joy of joys that worked too. Something is going to go wrong somewhere along the line!!!!!

The motors were in, the battery boxes screwed on and makeshift ankle wedges in place for R2 to start rolling using a RC transmitter and receiver from the very first thing I bought with my very first credit card - a Tamaya Ford Escort Cosworth. R2 gently made his way through all the cars and positioned outside the window for all the guests to see. And to be honest I was pretty chuffed with how he was going, turning on the spot, forwards, backwards - absolutely fantastic. The best bit was how surprised the wife was - helps negotiate for more funds.

Sunday 9 December 2012

What's happening? Not a lot!!!

These blogs are getting very infrequent. I must do more!!!

I have not really done a lot since the last one. Except move the supports for the long front arm slots so that they face forward(ish) as opposed from the centre point. This will enable the use of arms coming out to the front instead of the side. Someone mentioned it somewhere and it was a "Oh yeah!" moment. Also James from the UK R2 Builders mentioned that he has had to strengthen his shoulders so this has been done also.

Even though the dome is untouched, I wanted to get the displays working so I have been soldereing the components on. In line with everyone else I put some LEDs in to make sure it all worked and only 1 set of them worked!!!!! After about 18+ hours of investigating, swapping bits over, resoldering, testing with a multimeter and writing down what IC pin went where all with a X10 magnifying glass stuck to the eye, it transpires that there is a small break between pins joining the first IC to the 2nd (and thus the 3rd). A small jumper wire soldered on and hey presto! we're in business. Now all I have to do is file the flange on the 135 LED's down so the bezel will fit.

So far about 50 done.

I have been wondering about the centre wheel and found a site on fleabay which was based a few miles away. Deciding to pop in the way home from work I managed to get a centre swivel 100mm castor for £6. It did look like I was going to have a smaller 75mm wheel for a time though. Bigger is better - especially when I get the suspension on it.

Time to go and file another few LED's.

I have not really done a lot since the last one. Except move the supports for the long front arm slots so that they face forward(ish) as opposed from the centre point. This will enable the use of arms coming out to the front instead of the side. Someone mentioned it somewhere and it was a "Oh yeah!" moment. Also James from the UK R2 Builders mentioned that he has had to strengthen his shoulders so this has been done also.

Even though the dome is untouched, I wanted to get the displays working so I have been soldereing the components on. In line with everyone else I put some LEDs in to make sure it all worked and only 1 set of them worked!!!!! After about 18+ hours of investigating, swapping bits over, resoldering, testing with a multimeter and writing down what IC pin went where all with a X10 magnifying glass stuck to the eye, it transpires that there is a small break between pins joining the first IC to the 2nd (and thus the 3rd). A small jumper wire soldered on and hey presto! we're in business. Now all I have to do is file the flange on the 135 LED's down so the bezel will fit.

|

| Bright Light!!! |

So far about 50 done.

I have been wondering about the centre wheel and found a site on fleabay which was based a few miles away. Deciding to pop in the way home from work I managed to get a centre swivel 100mm castor for £6. It did look like I was going to have a smaller 75mm wheel for a time though. Bigger is better - especially when I get the suspension on it.

|

| Where there's a wheel, there's a way!!! |

Time to go and file another few LED's.

Thursday 11 October 2012

Little steps

Its been a while - again!!!

But here's the latest installment.

I have finished marking and cutting the other 3 panels on the front inner skin. These are now ready to go. All I have to do is work out how I'm going to attach the skins to the frame. Just to make R2 a bit different to the norm, I'm toying with the idea of countersinking allen key bolts into the frame and leaving them on show. This will save having to smooth over and paint and make skin removal easier if required. It may even look more factory built too.

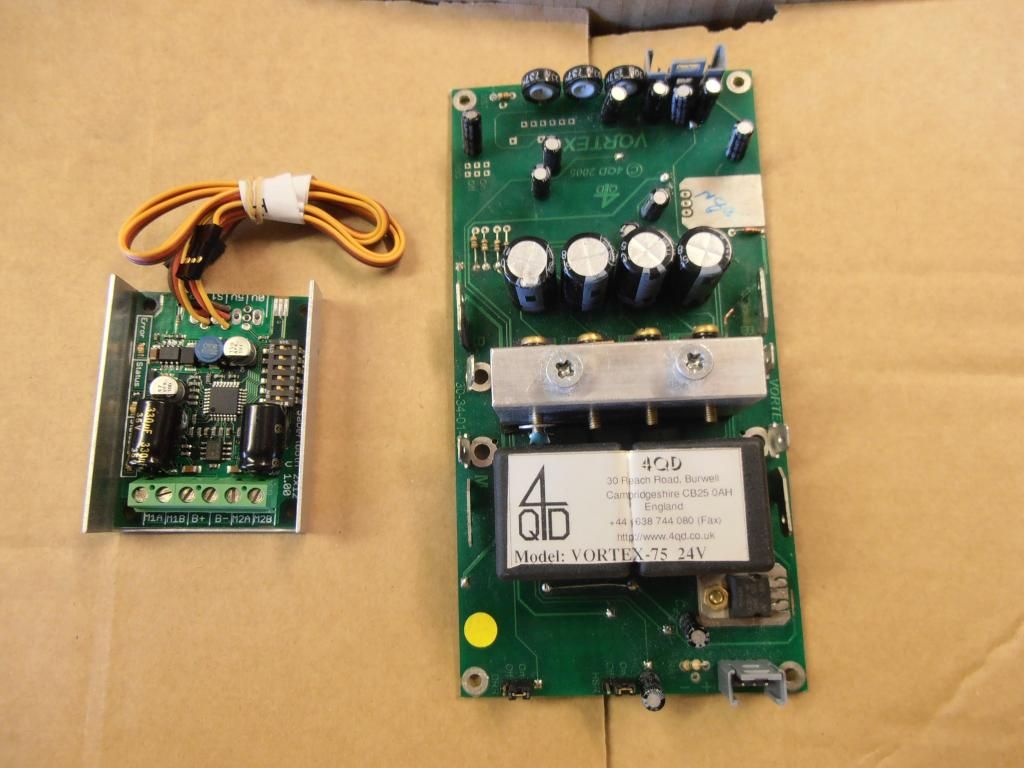

I've also been following a fellow builders updates on the forum about his adaption for the dome light displays. Being most impressed with BigHappyDudes progress I spent the remaining birthday money on a lot of bits to start this and a motor controller. The plan is for R2 to move by Xmas and join in the festivities and for Skye to start her part in the build and solder!!

Heres a photo of a few of the bits with more on the way - yippee!!

But here's the latest installment.

I have finished marking and cutting the other 3 panels on the front inner skin. These are now ready to go. All I have to do is work out how I'm going to attach the skins to the frame. Just to make R2 a bit different to the norm, I'm toying with the idea of countersinking allen key bolts into the frame and leaving them on show. This will save having to smooth over and paint and make skin removal easier if required. It may even look more factory built too.

|

| Oooh!! Shiny!!! |

I've also been following a fellow builders updates on the forum about his adaption for the dome light displays. Being most impressed with BigHappyDudes progress I spent the remaining birthday money on a lot of bits to start this and a motor controller. The plan is for R2 to move by Xmas and join in the festivities and for Skye to start her part in the build and solder!!

Heres a photo of a few of the bits with more on the way - yippee!!

|

| An early Xmas present! |

I couldn't get over how small the dual motor controller was compared to the 4QD one for Skye's Toylander

Friday 14 September 2012

Gulp!!!

It's been a while since I've done anything to R2 - school hols, work etc.

But, now my co-builder is back at school I can start making a bit of progress again.

A bit of where shall I start in the DMW and I decided to crack on with the panel cutouts on the skins.

Gulp!!! If I get this wrong then its scrap the skins and make them from styrene.

I had scribed the cut linefor the inner skin and with a 0.75mm thick cutting disc in the dremel away I went. The dremel must have been working hard because it must have stopped a dozen times due to a thermal cut-out. Eventually the inner piece was done.

Don't look too closely though otherwise you will see the lines aren't quite straight. It only took just over an hour to do, so the it will be atime consuming process. And the dome will take even longer as its thicker - great!.

Hopefully the updates will become a little more frequent now as my step-daughter has suggested R2 carrying her wedding ring next August.

But, now my co-builder is back at school I can start making a bit of progress again.

A bit of where shall I start in the DMW and I decided to crack on with the panel cutouts on the skins.

Gulp!!! If I get this wrong then its scrap the skins and make them from styrene.

I had scribed the cut linefor the inner skin and with a 0.75mm thick cutting disc in the dremel away I went. The dremel must have been working hard because it must have stopped a dozen times due to a thermal cut-out. Eventually the inner piece was done.

|

| Good the flash hides the dodgy bit!!! |

Don't look too closely though otherwise you will see the lines aren't quite straight. It only took just over an hour to do, so the it will be atime consuming process. And the dome will take even longer as its thicker - great!.

Hopefully the updates will become a little more frequent now as my step-daughter has suggested R2 carrying her wedding ring next August.

Sunday 29 July 2012

Sun's out - must be time to go in the garage!!

I bet you all thought R2 was going to remain a half-finished project. Well, your wrong and as usual I'm right.

Today was the first time in a long, long time that I managed to get in the DMW and carry on with some of the build. That's not quite true I have started on a horseshoe.

It was time to wet and dry the legs, ankles, feet and battery boxes. I have since the last blog been out there and filled and sanded a few bits but didn't think it worthy to write about. Once these where sanded a quick wipe over with some meths getting into the small areas and then placed into the new spraybooth (cardboard on the floor of the van). Just to make sure that the parts were filled I used some plastic filler primer from Halfords. Not to sure what its going to be like but its yellow so I can see where I have sprayed. Thes will be left in the van till Tuesday.

The shim on the horseshoe was added and then before tea I thought I'd have a look at the skins. I decided to take the plunge and start cutting out a door. Once this was done a needle file removed the small burrs. I only cut out the one door frame as I don't want to mix them up.

A set of coin slots from Don Jarr was stuck into the inner skin to make them look good. That was it for the day but I didn't start time lunchtime and had lunch after an hour too!! Got to keep the energy reserves up.

I do have Banebot wheels now ready for the motors. And once the legs are together I can work out what size of castor is needed for the centre foot.

Today was the first time in a long, long time that I managed to get in the DMW and carry on with some of the build. That's not quite true I have started on a horseshoe.

It was time to wet and dry the legs, ankles, feet and battery boxes. I have since the last blog been out there and filled and sanded a few bits but didn't think it worthy to write about. Once these where sanded a quick wipe over with some meths getting into the small areas and then placed into the new spraybooth (cardboard on the floor of the van). Just to make sure that the parts were filled I used some plastic filler primer from Halfords. Not to sure what its going to be like but its yellow so I can see where I have sprayed. Thes will be left in the van till Tuesday.

|

| Another sanding due when dry. |

|

| The first door is cut. |

|

| Coin slots in and ready to receive. |

A set of coin slots from Don Jarr was stuck into the inner skin to make them look good. That was it for the day but I didn't start time lunchtime and had lunch after an hour too!! Got to keep the energy reserves up.

I do have Banebot wheels now ready for the motors. And once the legs are together I can work out what size of castor is needed for the centre foot.

Wednesday 23 May 2012

Getting filled in!!!!

Well, not a lot on the build front due to holiday preparation to see Star Wars Weekends in Florida plus the other attractions of course.

So the two main feet have had the fancy trim stuck on and to help strengthen them the DIY car repairers buddy - P38. A dollop of this was mixed up and worked into any gaps and on the inside (out of view) to give these little bits a help should/when R2-ST hits an unmoveable object e.g. kerb.

R2-ST has its first event planned at Invasion Colchester in August even if its not ready, which I know it wont be. The event is to raise money for charity and has people dressed as characters from tv & film.

Should be good to put faces to names etc too.

Anyway this is what both feet look like with a bit more preparation to do

.

|

| Oooohhhh! Nice! |

R2-ST has its first event planned at Invasion Colchester in August even if its not ready, which I know it wont be. The event is to raise money for charity and has people dressed as characters from tv & film.

Should be good to put faces to names etc too.

Anyway this is what both feet look like with a bit more preparation to do

|

| Looking good Houston. |

Friday 11 May 2012

A little bit of this...

My time in the Design & Maintenance Workshop has been spent finishing the halfmoons for the main feet and getting them flat. This meant that they could be glued on and what a difference they made to the foot. It's all slowly coming together now.

Today, I managed to deaden the nerves in my index finger, by using a scalpel (with a new blade just in case I decided to cut myself again) and cutting the detail pieces for the main feet. The styrene is only 1mm but in order to cut the slots out it meant going over the lines getting deeper and deeper each time. All together there was/were 40 slots to cut out measuring about 25mm x 5mm. How sad is that knowing the size!!!!

It didn't take too long to cut either, once I'd got in the rythym. I even had a little set-up seeing the angle they go to etc, etc..

After this it was a quick mix of the good ol' car filler P38. to smooth over some of the ridges in the battery boxes . The smell bought back some memories of my younger years, but I had obviously forgotten the ratio as I had just managed to smear it over the boxes when it went hard. Thankfully I had mixed the right amount just too much hardener - a mental note for next time.

I'll leave them to completely set while I'm back at work then have a go at sanding/filing them smooth.

Everything is slowly starting to come together, but still a lot to do. Hey!Ho! good job no deadline.

|

| The weathered look? |

Today, I managed to deaden the nerves in my index finger, by using a scalpel (with a new blade just in case I decided to cut myself again) and cutting the detail pieces for the main feet. The styrene is only 1mm but in order to cut the slots out it meant going over the lines getting deeper and deeper each time. All together there was/were 40 slots to cut out measuring about 25mm x 5mm. How sad is that knowing the size!!!!

|

| Finish the slots before tea - I hope! |

After this it was a quick mix of the good ol' car filler P38. to smooth over some of the ridges in the battery boxes . The smell bought back some memories of my younger years, but I had obviously forgotten the ratio as I had just managed to smear it over the boxes when it went hard. Thankfully I had mixed the right amount just too much hardener - a mental note for next time.

I'll leave them to completely set while I'm back at work then have a go at sanding/filing them smooth.

|

| Good, the photos don't show the lumps. |

Thursday 3 May 2012

At last - a 2nd Battery box

Yes, as you can guess from the post title I have finally made the second battery box. What's taken you so long? I hear you ask. Well, in a nutshell I couldn't be bothered to make it with all those curved bits but after giving myself a good talking too it has been completed.

The main parts were cut and glued yesterday which was nice and straight forward making a box.

Today was the day both boxes would get their second skin.

It was easy to cut being 1mm styrene. An idea I copied from somewhere was to give the door a lip. I decided 5mm all round would be good, so instead of following the line a new one was made 5mm bigger. Lining this up on the 3mm stuff was easy but one thing to be aware off is it leaves very little styrene before the curve section. I would recommend that this left to dry overnight before glueing the curve. But I didn't want to do that, so I had a bash at glueing the curves on. This involved some copious lengths of masking tape to keep the 1mm stuff in contact.

That's as far as I got today and I'm please with it. By the time I get back to the DMW they will be ready to finish off.

|

| To many curves!!! |

|

| Simples!! |

Today was the day both boxes would get their second skin.

|

| Order another pallet of masking tape please!!! |

That's as far as I got today and I'm please with it. By the time I get back to the DMW they will be ready to finish off.

Sunday 29 April 2012

Rain doesn't stop play....yet!!!!!

A very damp day and work that night mean't some time was allowed in the DMW.

I decided to start trying to finish all the unfinished parts which kinda makes sense.

The detail pieces on the side of the main feet were cut out and glued on and a half moon

was finished off. Its starting to look so much better with theses little bits done.

The 1mm side pieces on the centre foot were cut out rather easier than the same bits on the main feet. Once suck to the 2mm pieces they were filed to fit and glued in with masking tape to hold position.

That was it for the few hours in the DMW, and it was a bit chilly out there due to the heavy rain, but it could have been worse. The main thing is it got me away from Monopoly (normal and Star Wars vesions) with Skye. Winning all the time can get boring.

|

| OOOOH! Nice |

I decided to start trying to finish all the unfinished parts which kinda makes sense.

The detail pieces on the side of the main feet were cut out and glued on and a half moon

was finished off. Its starting to look so much better with theses little bits done.

|

| More tape than you can throw a stick at. |

That was it for the few hours in the DMW, and it was a bit chilly out there due to the heavy rain, but it could have been worse. The main thing is it got me away from Monopoly (normal and Star Wars vesions) with Skye. Winning all the time can get boring.

Sunday 22 April 2012

Look at my skirt!!!

At long last I have managed to work out the skirt. It's taken a while but looking at Jerry Greene's schematic I worked out the angle for the curved skirt pieces. From this, new support triangles were cut out and glued in. The curved skirt pieces were then duly stuck down and left while I went to work.

Today, after beating Skye at monopoly, I was allowed (!) into the DMW (Design & Maintenance Workshop). All the skirt ribs have been filed to the same size and then it was a case of where abouts they went on the skirt. A few cups of tea, a look on the computer and I realised there were marks on the base plate - DOH! With the centre line marked as soon as one side was completed and symetrical, the other end was a piece of cake (or another cup of tea).

Before today I did manage to put the curved 1mm piece on the other foot. This did take 3 attempts though as the plastic kept splitting but perserverance paid off.

Tomorrow may see the other battery box made - but who knows!!

Today, after beating Skye at monopoly, I was allowed (!) into the DMW (Design & Maintenance Workshop). All the skirt ribs have been filed to the same size and then it was a case of where abouts they went on the skirt. A few cups of tea, a look on the computer and I realised there were marks on the base plate - DOH! With the centre line marked as soon as one side was completed and symetrical, the other end was a piece of cake (or another cup of tea).

Before today I did manage to put the curved 1mm piece on the other foot. This did take 3 attempts though as the plastic kept splitting but perserverance paid off.

Tomorrow may see the other battery box made - but who knows!!

Monday 9 April 2012

More Bank Holiday pleasure

It never rains, it pours. How true is that statement. A planned trip out was cancelled due to the weather and saving up for our vacation (Skye's wording) to Florida. So after a morning on the kinect and playing twister with Skye made all the more interesting with the wife not spinning the wheel but pre-determining the movement. it was time to venture to the D&M centre.

On the agenda today was, the 1mm curved piece on a foot for the battery box. Using ideas from another builders blog on using aerosol cans to hold the curve and away we go. After a few hours the clamps were removed and the cut-out made.

WOW! what a difference that makes.

TA-DA! Nearly finished foot

While the foot was drying, a further section was stuck on the skirt support pieces. This went a whole lot better than the first time with no splits occurring and all of my clamps used up. As the hours rolled by the only pieces left to glue was the final ends.

Just to have something else started and not finished, I decided to have a closer look at the excellent Deetoo Skins. As I want the doors to open I started to remove the scrap panels on the outer skin so I can line up the skins and draw around the door frame onto the inner skin. A blunt chisel was used on the tags on the scrap piece to wear the aluminium down so that the scrap could be twisted out. A small pair of side cutters removed the tag which will be filed at a later date.

Once the skins are lined up and the door frame marked, it will be a case of removing the frame and marking the opening. The worst bit will be dremelling in between the two lines to make the lip for the door to sit on. Gulp! Do I really want opening doors? This will be blogged when I summon up the courage to do it an dwhen I have full use of all 10 digits. The skin does look a bit better with the scrap parts removed though.

|

| If only everthing was this simple! |

WOW! what a difference that makes.

|

| Where's Eddie the Eagle? |

TA-DA! Nearly finished foot

|

| The end is nigh! |

|

| Looking good |

Once the skins are lined up and the door frame marked, it will be a case of removing the frame and marking the opening. The worst bit will be dremelling in between the two lines to make the lip for the door to sit on. Gulp! Do I really want opening doors? This will be blogged when I summon up the courage to do it an dwhen I have full use of all 10 digits. The skin does look a bit better with the scrap parts removed though.

A little Bank Holiday pleasure

A busy Easter weekend but still some time to visit the deveolpment and maintenance centre (garage).

The skirt had been drying to the body when I thought the curve section should be 1mm - so I cut the 3mm stuff off. Put some 1mm styrene on and started tidying up the detail edges on the feet with my lovely brand new very sharp scalpel and guess what? Yep, I managed to slice the tops of two fingers. No swearing occurred but instinct cut in and the thumb held the worst wound together while I clamped the parts together.

A visit to the kitchen saw a plaster and micropore tape put over both fingers to hold the cuts together.

Back to the D&M centre with blood oozing through the covers and I decided to go indoors and research. Few minutes later and the wife noticed and cringed, Skye went "cool! canI see".

Worst news was to follow though - while researching I could see that the curved sections are in fact 3mm - NOOOOOO!!!!!!

Back outside and 1mm parts off and 3mm parts stuck/clamped on and left to dry overnight.

That's better than first time too!!!

The skirt had been drying to the body when I thought the curve section should be 1mm - so I cut the 3mm stuff off. Put some 1mm styrene on and started tidying up the detail edges on the feet with my lovely brand new very sharp scalpel and guess what? Yep, I managed to slice the tops of two fingers. No swearing occurred but instinct cut in and the thumb held the worst wound together while I clamped the parts together.

A visit to the kitchen saw a plaster and micropore tape put over both fingers to hold the cuts together.

|

| A clear plaster, it was |

Worst news was to follow though - while researching I could see that the curved sections are in fact 3mm - NOOOOOO!!!!!!

|

| The day after the day before |

Back outside and 1mm parts off and 3mm parts stuck/clamped on and left to dry overnight.

That's better than first time too!!!

A Blown motivator????

This is'nt to do with R2 but I went to pick up Skye from school in her Toylander, no problems. Then on the way home we went to go gently up a kerb and - no power and a electrical burning smell. That was it power off push up the kerb and see if it would reset.

No such luck so lift the back by the rear suspension and a 600m carry home!!

Closer inspection reveals this -

Spot the burnt out resistors!!!! - 3rd repair job on this motor controller.

No such luck so lift the back by the rear suspension and a 600m carry home!!

Closer inspection reveals this -

Spot the burnt out resistors!!!! - 3rd repair job on this motor controller.

Sunday 1 April 2012

BIt of a ponder!!!

I should have updated this a few weeks ago but not a lot was achieved so I didn't bother.

The middle ankle was built and the main part of the centre foot. I stopped there for a bit while I thought about what wheel set up to have. Obviously 2 is better but what size will fit? People are using castors and changing wheels to inline skate type as they turn in better due to their profile - makes sense. I may go down this route but perhaps at a later date. After all it wont take long to knock up another foot - will it?

The wheel set up was another reason I hadn't finished the main feet either. Dave's plans call for a single wheel in each foot, but I was thinking about the 2-3-2 situation down the line and relieving the stress on the parts. Again this was something that could be done at a later date so I started to fix the final parts to these.

While all this was going on I started on the skirt. Blinking 'eck thos 3mm curved sections are difficult too do. Perhaps I should have followed the plans and done it stage by stage and not in one go. They have all split where they curve round but some styrene/glue paste has sealed them and they seem to have stuck on well.

It was now a case of stick this part of the skirt on to the frame before commencing further action, mainly because it was like Christmas as a child - THE SKINS ARRIVED.

It was now a case of stick this part of the skirt on to the frame before commencing further action, mainly because it was like Christmas as a child - THE SKINS ARRIVED.

Fantastic!

I waited for Skye to come home and open the box with me and couldn't help but have a big grin on my face all afternoon. Thanks to Deetoo from the UK R2 Builders Club for arranging this. The next few evenings were spent looking at domes and alternatives aswell as the cutting out of the door sections. In order to have some of the doors open on the body, I'm going to have to take a dremel and cut out the inner skin in order fot them to open. Only 4 on the front section, but it could be a case of just doing one for the charger and perhaps on the next droid having an all bleeping, all shaking one!!!

A lightshade from B&Q is very similar size to a proper dome was purchased but its about 6mm smaller in diameter. This is the ponder bit. When it comes to it do I try and hide this difference somehow and use this as a temporary measure or save for a proper dome? The jury is still out at the moment but with the skins round the frame and dome on top it looks better.

|

| Centre ankle plates drying together. |

|

| Curve sections taped in place |

|

| Centre Foot underway |

|

| Starting to look better. |

|

| Hands up, who sees the splits? |

While all this was going on I started on the skirt. Blinking 'eck thos 3mm curved sections are difficult too do. Perhaps I should have followed the plans and done it stage by stage and not in one go. They have all split where they curve round but some styrene/glue paste has sealed them and they seem to have stuck on well.

It was now a case of stick this part of the skirt on to the frame before commencing further action, mainly because it was like Christmas as a child - THE SKINS ARRIVED.

It was now a case of stick this part of the skirt on to the frame before commencing further action, mainly because it was like Christmas as a child - THE SKINS ARRIVED.Fantastic!

I waited for Skye to come home and open the box with me and couldn't help but have a big grin on my face all afternoon. Thanks to Deetoo from the UK R2 Builders Club for arranging this. The next few evenings were spent looking at domes and alternatives aswell as the cutting out of the door sections. In order to have some of the doors open on the body, I'm going to have to take a dremel and cut out the inner skin in order fot them to open. Only 4 on the front section, but it could be a case of just doing one for the charger and perhaps on the next droid having an all bleeping, all shaking one!!!

|

| Mind the gap. |

Can you guess what it is yet?

|

| Yep, an oversize trash can. |

Saturday 4 February 2012

SABOTEUR SPOTTED IN GARAGE!!!!!

I couldn't believe how cold it was when I took the day off studying and popped out to the garage for a little build therapy.

All wrapped up with eyes and hands on view, it was out to redo the curve on an ankle after I decided to put a clamp through it!!!!Doh!!

With that done it was a case of making the holes for the shoulder buttons. I managed to find a nifty little tool from Toolstation that if I had known about it earlier would have used it for the leg curve. Oh, well.

After the holes were made and some expanding foam moved from the cable pipe it was time to bolt the shoulder hubs on. Then the legs to the body.

With R2 watching, it was indoors to warm the fingers up and a cuppa before venturing back into the cold.

This time round it was the beginning of a battery box. Unsure how long it would take for the glue to set in the sub zero temperatures, I planned on not doing a lot. But like all well made plans the glue wasn't too bad and a nearly complete battery box was completed before the toes said they were going to turn to ice. Next time I shall wear boots instead of trainers. All said and done though, quite pleased with the progress today - just need the lottery win to buy the rest of the bits.

If it snows tonight it will be a difficult choice between studying, garage or sledging with Skye.Hmmmm! Sledging is ahead at the moment.

All wrapped up with eyes and hands on view, it was out to redo the curve on an ankle after I decided to put a clamp through it!!!!Doh!!

With that done it was a case of making the holes for the shoulder buttons. I managed to find a nifty little tool from Toolstation that if I had known about it earlier would have used it for the leg curve. Oh, well.

|

| A fabulous cutting tool for less than £10 |

After the holes were made and some expanding foam moved from the cable pipe it was time to bolt the shoulder hubs on. Then the legs to the body.

|

| R2's lost its head |

With R2 watching, it was indoors to warm the fingers up and a cuppa before venturing back into the cold.

|

| Not bad for a few hours building in -2 temperatures. |

If it snows tonight it will be a difficult choice between studying, garage or sledging with Skye.Hmmmm! Sledging is ahead at the moment.

Wednesday 4 January 2012

Who needs glue?

Nearly a month since my last blog but that doesn't mean I haven't done any work on R2.

My goal was by Christmas to have R2 able to stand up unsupported as long as no-one touched him. This wasn't achieved however because of school holidays - yep I had to stay indoors where it was warmer and annoy Skye. To cut a long story short, Skye was not feeling well the week before xmas and ended up having an emergency appendix operation on the 23rd December. She was discharged from hospital on Christmas Eve and is back to her annoying self. Anyway, while she was in hospital we decided it would be good to take R2 round the childrens ward when he's finished as a thank you to the staff and to cheer up the children. This adds a bit more pressure to make him look even better now - gulp!

I've digressed enough now and back to the build. I managed to escape the house for a few hours and headed to the garage where the 2nd foot was built to the same stage as the 1st. This meant R2 could stand unsupported and photo time. The obligatory photo of a persons head behind R2 was also taken.

Due to my shift pattern at work, I have managed to fit in another few hours in the cold garage. At one point I was wondering how I was going to get my lunch without getting wet as the rain streamed down. Then it eased and my worries were gone.

I was now cutting the 1mm HIPS. WOW!! how much easier is this to cut and snap than 3mm? This stuff is really, really nice to cut. The 1mm parts for the legs were cut out oversize in order to give enough material to trim up. After checking for high spots the strips going around the tops of the legs were glue on and held in place with tape. Only 1 strip on each leg at the moment though.

The next day after these had dried the 2nd strip was added and again held in place with tape.

There is so much tape around these sections that its a pity glue is applied. While these strips were drying a trim of the slots and a file of the angle bits and another part of the legs are covered in 1mm.

My goal was by Christmas to have R2 able to stand up unsupported as long as no-one touched him. This wasn't achieved however because of school holidays - yep I had to stay indoors where it was warmer and annoy Skye. To cut a long story short, Skye was not feeling well the week before xmas and ended up having an emergency appendix operation on the 23rd December. She was discharged from hospital on Christmas Eve and is back to her annoying self. Anyway, while she was in hospital we decided it would be good to take R2 round the childrens ward when he's finished as a thank you to the staff and to cheer up the children. This adds a bit more pressure to make him look even better now - gulp!

I've digressed enough now and back to the build. I managed to escape the house for a few hours and headed to the garage where the 2nd foot was built to the same stage as the 1st. This meant R2 could stand unsupported and photo time. The obligatory photo of a persons head behind R2 was also taken.

| Skye with the compulsory picture |

Due to my shift pattern at work, I have managed to fit in another few hours in the cold garage. At one point I was wondering how I was going to get my lunch without getting wet as the rain streamed down. Then it eased and my worries were gone.

I was now cutting the 1mm HIPS. WOW!! how much easier is this to cut and snap than 3mm? This stuff is really, really nice to cut. The 1mm parts for the legs were cut out oversize in order to give enough material to trim up. After checking for high spots the strips going around the tops of the legs were glue on and held in place with tape. Only 1 strip on each leg at the moment though.

| 2nd strip taped in place.Who needs glue? |

| Slot bits drying - hopefully! |

There is so much tape around these sections that its a pity glue is applied. While these strips were drying a trim of the slots and a file of the angle bits and another part of the legs are covered in 1mm.

While in the garage I played with some filler called Milliput. It was bought from a local railway model shop and has some excellent uses and only cost £3. Once mixed by hand like dough it was put in a few places on the feet and when set can be filed, sanded, drilled, tapped etc. This could be my saviour if I'm going to display at the hospital. I'll let you know how this part goes.

| The magic of Milliput? |

I'm back at work tomorrow, and I had best start studying for a couple of exams in 8 weeks, so the build may be a bit slow. But while studying on the laptop I could start playing with Picaxe programming now I have the stuff - hmmm!!!

Gosh! Nearly forgot Star Wars on blu-ray - absolutely fantastic. Although Skye did threaten to destroy the discs if I kept saying quoting lines before the actors. Obviously I humoured her - for a while

Subscribe to:

Posts (Atom)